At Blastec®, we engineer, build and install the world’s most technologically-advanced shot blast machines. Our innovation is unmatched within the large-scale manufacturing and industrial space.

Our machines are engineered and built to the highest quality standard, reducing the reliance on high-maintenance parts. Less turnover means less down time and higher production.

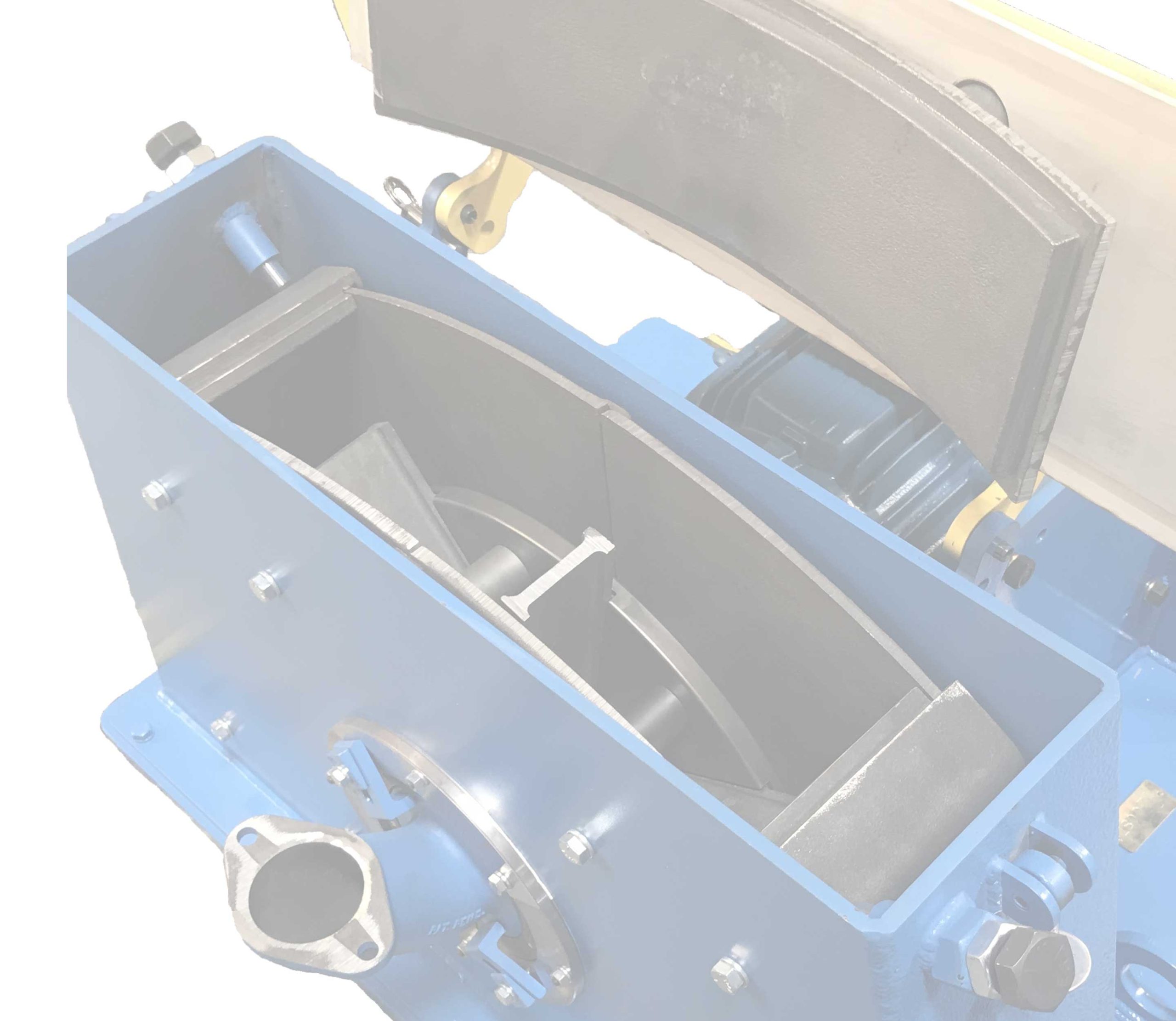

Reduce energy costs with our multi-patented 24-inch diameter Blastec® wheel. It operates at a cool, efficient 1,760 RPM, using less energy. Combined with our media-saving Shot Saver® system, your operating overhead will be reduced exponentially.

Blastec has more than 45 years of experience developing custom, heavy duty shot blasting solutions for businesses in a number of industries. Our products are designed with a focus on high performance and efficiency, and thrive in high production environments. All of our machines and are custom fabricated in our facility in Atlanta, Georgia to your exact needs and specifications.

Blastec® machines are designed and engineered to our customers’ individual requirements and specifications. Every component is assembled with a critical eye towards quality by our in-house fabrication team.

Since our founding in 1976, we have continued to set the standard in the shot blast industry.

Blastec® is the originator of the 1,760 RMP direct drive shot blast wheel. Since its introduction in 1976, many others have attempted to equal our success. Now in its 10th generation, our blast wheel still remains the leader in the industry.

Our Shot Saver® (patent pending) reduces abrasive media waste, saving you a significant percentage of consumption costs per year. Ensures no good abrasive is lost in the fine refuse.

All of our products are made on location in metro Atlanta, Georgia. By supporting our domestic production, you not only experience the best quality but also contribute to the growth of the American economy. Choosing Blastec means fostering a stronger sense of community while fostering the growth of an American-owned business. With each project, you are making a tangible impact on the livelihoods of our skilled workers and helping sustain local businesses across the nation.