Since its introduction in 1976, many others have attempted to equal our success.

WHAT KEEPS US AHEAD OF THE PACK? Our design. Now in its 10th generation, our original concept still remains the leader in the industry: A large diameter wheel turning at a low RPM and delivering the maximum amount of abrasive per square inch. While we have improved the maintenance aspects of the Blastec® wheel through these generational changes, parts for all wheels remain available and each generation is easily upgradeable to current specs.

Increase in Productivity

or More Blade Life Extension

or more impeller and control cage life extension

Reduction in Noise Levels

USE OF THE BLASTEC® WHEEL increases productivity by up to 50% and extends the life of the blades by 100% or more, and impeller and control cage life by 300% or more, compared to competitive models. In production tests and operating cost studies, the Blastec® wheel outperforms conventional 13 inch – 19 1/2 inch diameter, 2,250 – 3,600 RPM wheels. It also lowers dBA noise levels by up to 20% compared to the V-belt wheel assembly, and thus eliminates the need for sound suppressors.

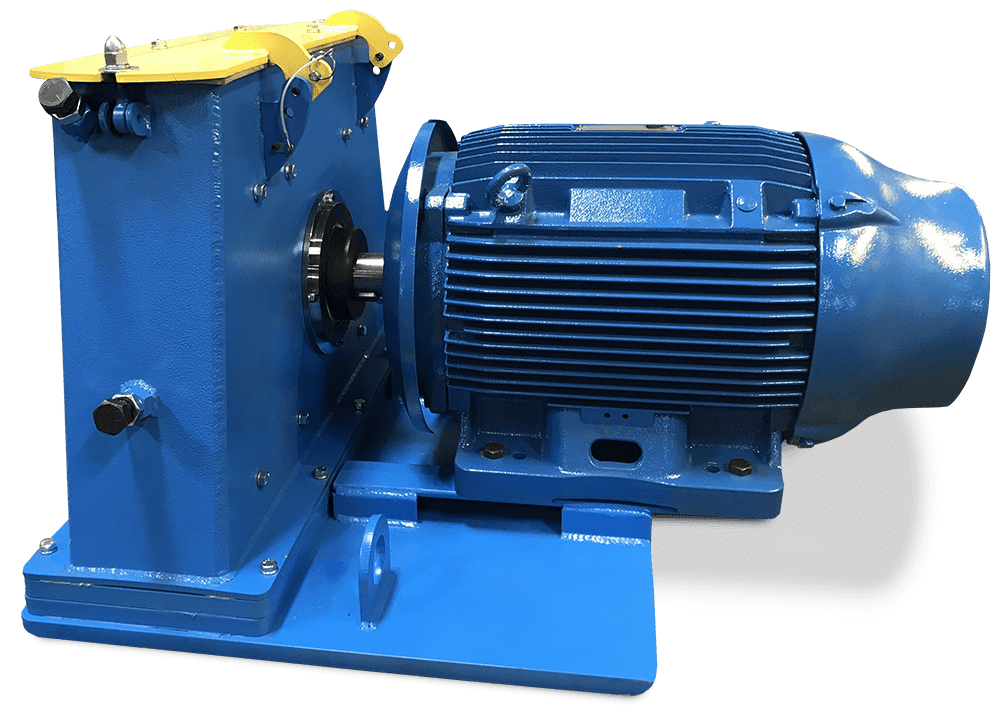

THE MULTI-PATENTED 24-INCH DIAMETER Blastec® wheel incorporates a double-sided runnerhead design, and two- sided, reversible blades of long and narrow design features. Operating speed is a cool, efficient 1,760 RPM. To improve performance standards, Blastec® engineers pioneered the concept of low RPM, direct drive between motor and wheel.

Horsepower robbing, high-maintenance items such as spindle and pillow block bearings, sheaves, and V-belts have been eliminated. This design assures maximum transmission of net motor energy to the blade tips, optimizing shot velocity and pattern efficiency.

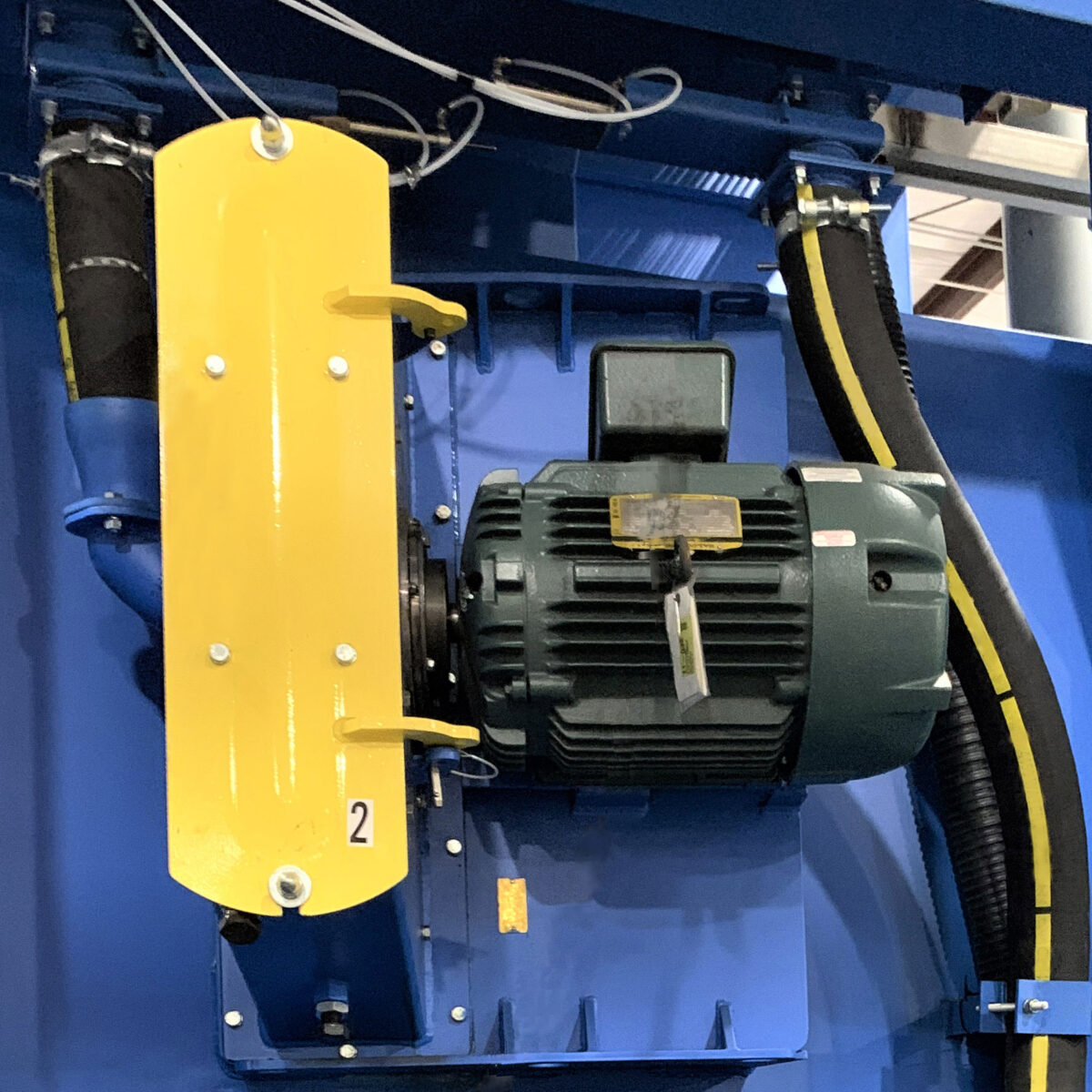

The Blastec® wheel is bi-directional, it is designed to rotate in either direction (CW or CCW) at its full capacity in motor sizes ranging from 15-125 HP. The same wheel parts are employed regardless of rotational direction or horsepower – so there is no need to stock different replacement parts for different applications. Therefore, in multi-wheel facilities, parts inventory requirements are greatly reduced.

Blastec® is the only manufacturer that guarantees to ship replacement parts for any Blastec® Wheel manufactured in its 40 year history within (24 HOURS), or we pay the freight.

The Blastec® wheel is specifically designed to simplify maintenance procedures. The double sided runnerhead Is constructed of extremely durable alloy steel. It is machined to exacting tolerances, heat treated, and balanced to the toughest quality standards. Blades are easily removed for replacement, or can be flipped end-for-end and reinstalled, all through the top lid opening without the inconvenience of removing the impeller, control cage or feed spout assembly. Side and end liners can also be removed without disturbing any of the wheel’s moving parts. As a result of this superior design, overall maintenance time is significantly reduced.

The Blastec®wheel is the perfect candidate when considering upgrading your existing shot blast machine. Each Blastec®wheel is shipped completely assembled. The industrial electric motor, along with the steel housing and hinged lid are mounted to a Blastec®heavy-duty base plate. Factory pre tested, the wheel is ready for installation and operation with minimal setup. An installation drawing illustrating the exact wheel location required for optimum performance is also provided. Blastec® offers installation and start-up assistance or complete turn-key installation.